More than just procurement.

A strategic, purpose-built network

Sourcing capabilities for any point in the process

Whether we’re helping to make iterations on a prototype build or preparing for a manufacturing run of thousands of pieces, ACD’s network of suppliers enables us to provide any service and acquire any material our customers may need to achieve their dream product.

Our team’s experience building global supply chains allows us to offer a vast range of services that include fast-turn prototype and production tooling, appearance model builds, PCB fabrication, and assembly services such as heat staking, thermobonding, and ultrasonic and laser welding. ACD’s meticulously selected partners enable us to meet any domestic or international certification requirements.

ACD’s bread and butter is designing and building electromechanical and electronic components, PCB/FCB/Rigid flex boards, cables, and custom connectors. Still, the connections we’ve made with our trusted partners ensure we can complete any job using any material or method our clients might require. From textiles to urethane and silicone casting, we’ve got what you need. Use the dropdown menu to explore our sourcing capabilities.

-

3D printing

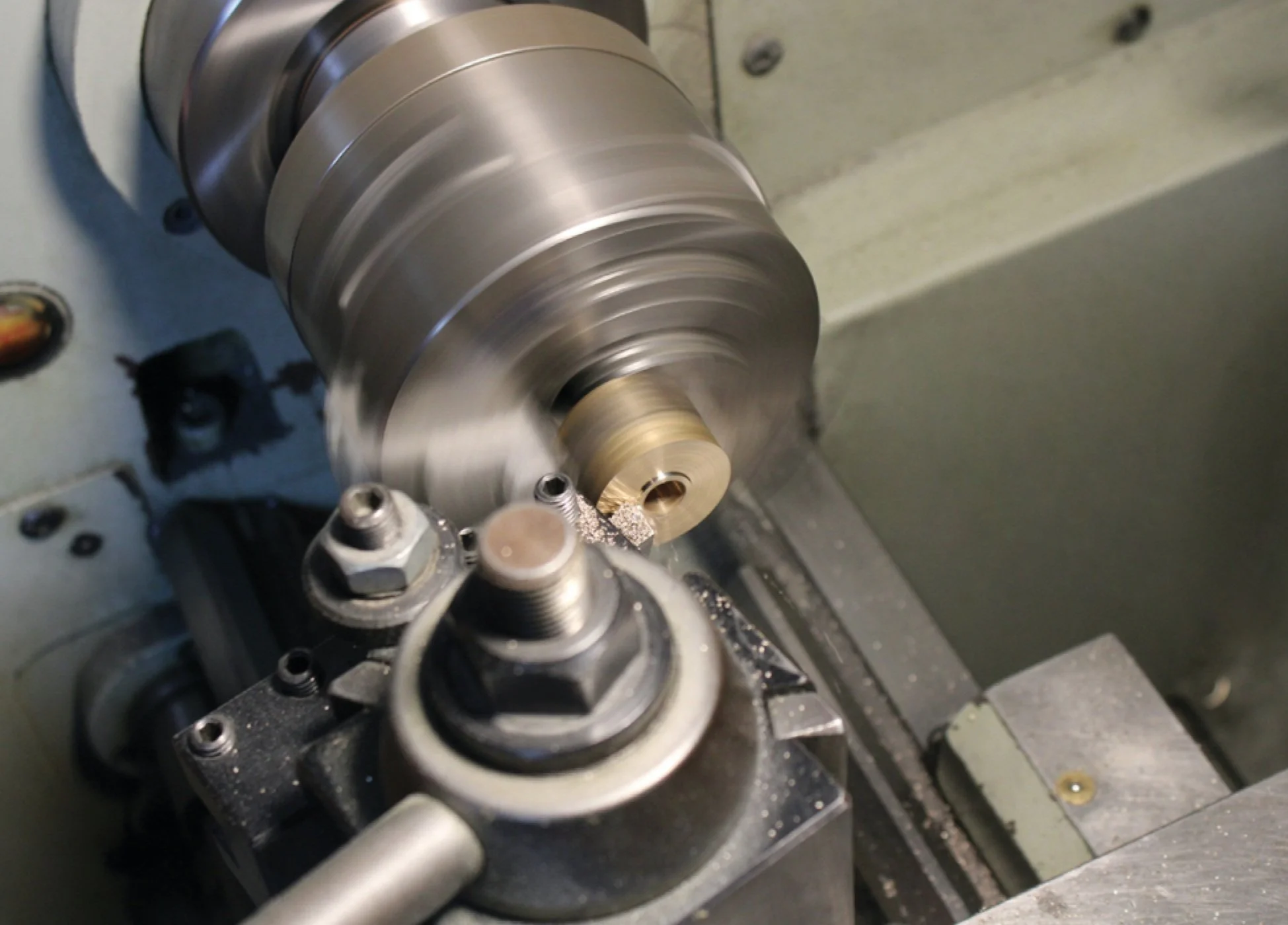

CNC machining

Urethane and silicone casting

Finishing and decorations

-

Plastic

Silicone

Liquid silicone rubber

Die casting

Metal stamping

CNC machining

-

Printing

Painting

Vacuum metallization

Non-conductive vacuum metallization

Anodizing

Physical vapor deposition

Heatstaking

Thermobonding

Ultrasonic and laser welding

-

Textiles

Fabrics